Large High Speed Grinding Chamber Stainless Steel Industrial Commercial Coffee Bean Grinder

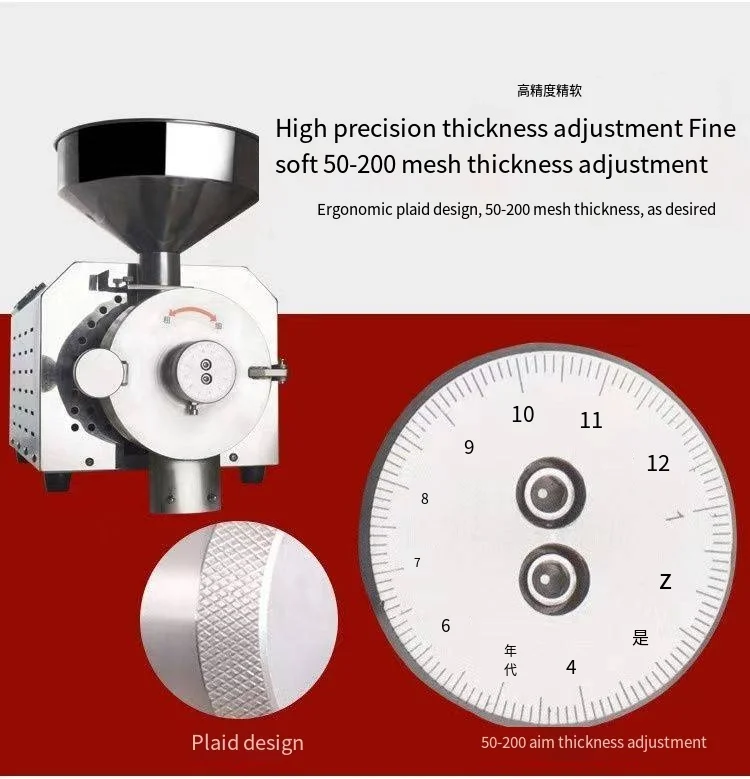

Specification:The new type 830 milling machine no longer used motor with low power supply.220V has 2.2KW and 3KW for option and 380V onlymatches with 2.4KW . The new type one is equipped with longer motor shaft than old one, which only use the other ...

Description

Specification:

The new type 830 milling machine no longer used motor with low power supply.220V has 2.2KW and 3KW for option and 380V only

matches with 2.4KW . The new type one is equipped with longer motor shaft than old one, which only use the other axis to sleeve on

the motor bearings to further ensure the concentricity angle and operation of the machine becomes more stability, less vibration

and less noise.

2. Adding silica gel pad between static grinding blade and machine wall,make sure it can reduce vibration and reach the effect of

milling blade micro-adjustment.Ensure that double-blade grinding board is firmer,grinding powder is finer and lower noise.

3. The space both in the middle of a motor and a motor fixing plate and the motor fixing plate below were added with rubber pad to

further strengthen the shock absorption and noise reduction effect.

4.The structure between the machine door cover and milling cavity adopts the tight fabrication way and step position assembling

way to ensure no leakage of powder and the concentricity angle of top pad of regulator and six angle sets of grinding disc,reduce

abrasion,make it lower vibration and noise.

5.The slope of grinding cavity,which is located on the position of fixed pulverizing blade,adopts scientific design to further

guarantee the fineness of milling powder in order to reach instant taste effect entering the mouth.

6.Molar of regulator adopts advanced mechanical processing to ensure the fabrication precision and reach the convenient

adjustment, tight installation, less noise.

7.After the pulverizing blades and scraping blades are installed on the grinding disc of the machine,the computer detects motion

balance to make sure the balance of the concentricity degree and gravity,to reduce the vibration and noise at maximum.

8.There is no bearing in the middle of chassis of grinding machine and motor.It is convenient for customers to dismantle it,reduce

the troubleshooting and promote the machine quality.

9.Comparing to the old one,the new one has the advantages which is good unloading,more fineness of powder,less noise and lower

vibration.

matches with 2.4KW . The new type one is equipped with longer motor shaft than old one, which only use the other axis to sleeve on

the motor bearings to further ensure the concentricity angle and operation of the machine becomes more stability, less vibration

and less noise.

2. Adding silica gel pad between static grinding blade and machine wall,make sure it can reduce vibration and reach the effect of

milling blade micro-adjustment.Ensure that double-blade grinding board is firmer,grinding powder is finer and lower noise.

3. The space both in the middle of a motor and a motor fixing plate and the motor fixing plate below were added with rubber pad to

further strengthen the shock absorption and noise reduction effect.

4.The structure between the machine door cover and milling cavity adopts the tight fabrication way and step position assembling

way to ensure no leakage of powder and the concentricity angle of top pad of regulator and six angle sets of grinding disc,reduce

abrasion,make it lower vibration and noise.

5.The slope of grinding cavity,which is located on the position of fixed pulverizing blade,adopts scientific design to further

guarantee the fineness of milling powder in order to reach instant taste effect entering the mouth.

6.Molar of regulator adopts advanced mechanical processing to ensure the fabrication precision and reach the convenient

adjustment, tight installation, less noise.

7.After the pulverizing blades and scraping blades are installed on the grinding disc of the machine,the computer detects motion

balance to make sure the balance of the concentricity degree and gravity,to reduce the vibration and noise at maximum.

8.There is no bearing in the middle of chassis of grinding machine and motor.It is convenient for customers to dismantle it,reduce

the troubleshooting and promote the machine quality.

9.Comparing to the old one,the new one has the advantages which is good unloading,more fineness of powder,less noise and lower

vibration.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

IS

IS

KA

KA

BN

BN

KK

KK

UZ

UZ

KY

KY